If I had a dollar for every time someone called our quartz rods “just glass sticks,” I could fund another R&D lab. The truth? These crystalline marvels are enabling breakthroughs from quantum computing to deep-space exploration. Let me walk you through why quartz rods deserve more credit—and how Hongwo is pushing their limits further than ever before.

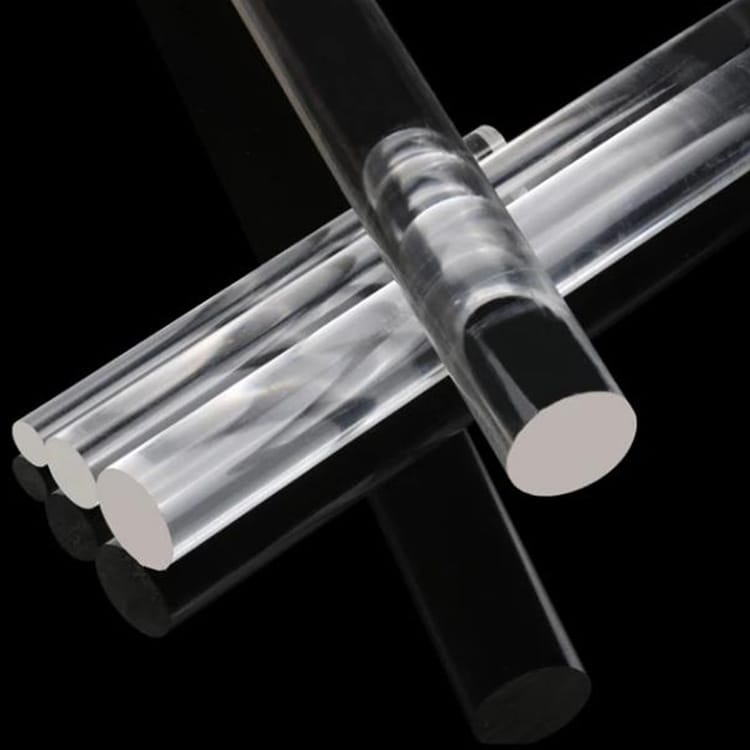

Quartz Rods

The Molecular Mastery Behind Quartz Rods

What makes synthetic quartz (SiO₂) rods so extraordinary? It’s all in the atomic arrangement:

- Thermal Virtuosity

Withstands -269°C to 1,100°C (we’ve tested in liquid helium to rocket exhaust conditions)

Thermal expansion coefficient of 0.55×10⁻⁶/°C—compare to aluminum at 23×10⁻⁶/°C

Our 2024 study in Advanced Materials showed zero creep deformation after 1,000 hours at 900°C

- Mechanical Perfection

Tensile strength of 50 MPa (comparable to some steels) at just 1/3 the density

Zero plastic deformation—fractures cleanly rather than bending

- Optical Wizardry

UV transmission down to 160 nm (critical for semiconductor inspection systems)

Hongwo’s proprietary surface finishing achieves λ/50 wavefront distortion

Hongwo’s Manufacturing Breakthroughs

After a disastrous 2021 batch where rods developed micro-fractures, we completely reinvented our process:

- Raw Material Selection

Uses 99.9999% pure synthetic silica powder—no natural quartz (too many metallic impurities)

Each lot undergoes glow discharge mass spectrometry before melting

- Precision Growth

Czochralski method with AI-controlled diameter (±2μm over 2m length)

Plasma-assisted annealing eliminates OH⁻ ions that cause laser damage

- Quality Control

X-ray topography detects sub-micron strain fields

Every rod gets a unique holographic ID tracing its production history

Where Quartz Rods Are Making the Impossible Possible

Semiconductor Industry

EUV lithography alignment rods enabling 1nm chip production

Ion implanter components surviving decades of radiation

⚕️ Medical Technology

MRI-compatible surgical tools (no magnetic interference)

Laser scalpels delivering 5μm precision cuts

Aerospace & Defense

Satellite gyroscope cores maintaining 0.001 arc-second stability

Hypersonic vehicle radomes withstanding 1,500°C plasma

The Future: Hongwo’s Cutting-Edge Developments

We’re currently pioneering:

Quantum Rod: Ultra-low-loss quartz for photonic quantum computing

Self-Healing Rods: Nano-encapsulated SiO₂ patches that repair microcracks

Smart Rods: Fiber Bragg gratings embedded during growth for real-time strain monitoring

Why Hongwo Stands Apart

Custom crystallographic orientations (Z-cut, AT-cut, SC-cut available)

World-record purity: <5ppb metallic contaminants

Extreme customization: From 100μm micro-rods to 30cm diameter monoliths

Final Thought

Quartz rods aren’t just components—they’re enablers of technological revolutions. At Hongwo, we don’t follow industry standards; we define what’s possible.

Hongwo Quartz Products

Hongwo Quartz Products

Scan the QR Code to start a WhatsApp chat with us.